塑料粉碎机的维护内容及方法

- 时间:2021-12-19作者:汕头经济特区震龙塑料机械有限公司浏览:192

适合转印:T恤、背包、帽子、服装(100%纯棉、50%棉、化纤、麻、毛、合成纤维,特别适合所有亮色服装)产地:中国 产品规格:A4 尺寸:210MM×297MM 产地:美国 1)适合任何普通喷墨打印机,建议用浩瀚烫画**墨水。 2)打印机选择模式选择照片或者优质照片模式,选择照片纸 3)镜像模式打印,如果是四色打印机请选择enhance图像增强 4)纸很贵重,请调整图像进行打印,避免浪费,浪费可耻 5)适合白色,淡蓝色,淡粉色,淡青色等诸多淡色衣服T恤 6)烫印之前请铺平T恤或者其他织物,烫印前可以用机器压 7)一般平板烫画机:185-190度 压力:重压 时间:10-15s 8)摇头烫画机器:180-190度 压力:重压 时间:8-12s 9)不可以用熨斗进行制作,因为压力和时间都达不到烫画机的要求,所以请不要浪费这种纸张做试验 10)热撕的哦,趁热撕下底纸,若撕不下来说明烫印时间短 11)可以用洗衣粉哦,或者机器洗涤,但是为了质量不用好 转印纸使用扫盲:转印纸使用需要注意几个问题如下: 1)使用烫画**墨水:墨水一定要选择烫画**墨水,推荐使用:浩瀚转印墨水,注意要区分普通墨水和烫画**墨水,这个是不一样的,浩瀚烫画**是耐光,高温不变色的,及时在烫画的时候颜色也是不会偏的。 2)烫画纸讲究几个参数:烫画温度,烫画时间,压力等等。 a、烫画温度,一般的转印纸烫画温度是185-200度之间,很多人很希望知道一个确切的值,但是这里要提醒的是,除非你是数字摇头的烫画机,需要一个类似于转印纸标出来的烫画温度,一般的都需要根据你的烫画机的实际情况来调节烫画温度,一般的直压式的烫画机,浅色转印纸温度在180度,深色转印纸的烫画温度在140-160度,而摇头的可以适当降低点或者不降低。深色的转印纸则一般在140度到160度之间。还是那句话,具体情况要根据自己的烫画机在各个参数里实验一下。 b、烫画时间:烫画时间就是在把烫画机压下的时间,通常浅色转印纸的时间是15s左右,深色在6-10秒之间,不过也仅仅是个参考,很多客户说自己的效果好像没有别人做出来的好,这很可能是照着经销商的数据直接做了,要知道各人的烫画机是不一样的,所以智慧的我们也应该根据实际的情况进行调整,以达到较佳的烫画时间以获得较好的烫画效果。 c、烫画压力:transmax的浅色都是重压,请把烫画机压力调到较大以达到较好效果。深色纸用的是轻到中等压力,还是那句话,根据自己的烫画机的情况,进行几次试验,调整到较好的状态。 公司网址

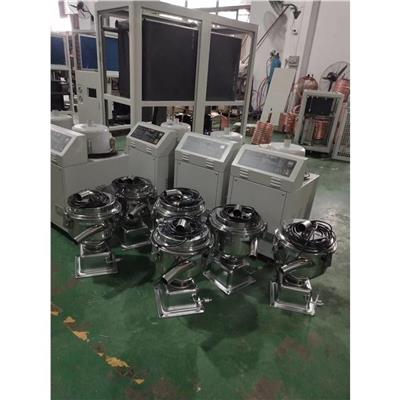

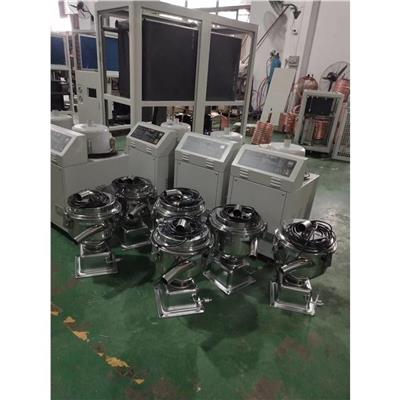

汕头经济特区震龙塑料机械有限公司专注于塑料粉碎机,塑料破碎机,强力塑料粉碎机,干燥混色机,混色机,冷水机,上料机等, 欢迎致电 13502966321

词条

词条说明

汕头500强力破碎机厂家,作为行业内知名的机械设备制造商,专注于生产高性能、高效率的破碎设备,其中500强力破碎机更是其明星产品之一。这款破碎机以其强大的破碎能力、高效的工作效率和稳定的运行性能,赢得了广大客户的青睐和好评。汕头500强力破碎机采用了先进的破碎技术和设计理念,确保了其在处理各种硬度和大小的物料时都能表现出色。其强大的破碎力来源于高性能的电机和优化的破碎锤头设计,能够轻松应对各种坚硬

广东300强力破碎机厂家,作为当前工业破碎领域的佼佼者,凭借其高效、耐用及强大的破碎能力,在众多破碎设备中脱颖而出,成为矿山开采、隧道挖掘、路基建设及混凝土破碎等重型工业应用场景的首选设备供应商。该厂家专注于研发、生产和销售各类破碎机设备,拥有深厚的技术积累和丰富的实践经验。其生产的300强力破碎机,采用了先进的液压马达驱动技术,提供了强大的扭矩和稳定的转速,确保了破碎效率和效果的最大化。同时,设

大型塑料粉碎机:一直以来作为废旧塑料批量粉碎处理的关键设备被广大塑料回收企业和塑料再生加工企业所应用,关于大型塑料粉碎机的定义及在废旧电视机外壳、空调外壳粉碎中的应用优势今天由河南油宝机械为您解答。废旧电视机外壳在材质上为ABS硬质塑料,在废旧塑料破碎过程中由于该类塑料在碎裂时会发出断裂声音锁业在破碎行业中也被称为响料,该类废旧塑料在破碎过程中由于其硬度较大使用一般的塑料粉碎机是很难将其破碎的,塑

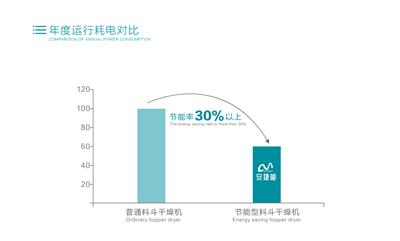

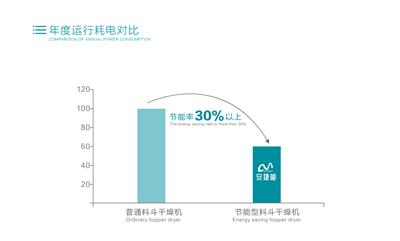

在现代工业生产中,干燥机作为一种重要的设备,发挥着不可或缺的作用。尤其在食品、制药、化工等行业,干燥机的应用更是随处可见。作为一家专业的机械设备生产厂家,汕头经济特区震龙塑料机械有限公司凭借多年的行业经验,专注于干燥机及其他塑料辅助机械的研发与生产,为客户提供高性能、优质的干燥解决方案。干燥机的重要性干燥机的主要功能是去除物料中的水分,以达到提高物料稳定性、延长保质期以及提高存储和运输效率的目的。

联系方式 联系我时,请告知来自八方资源网!

公司名: 汕头经济特区震龙塑料机械有限公司

联系人: 黄馨锐

电 话: 075482125236

手 机: 13502966321

微 信: 13502966321

地 址: 广东汕头金平区汕头市金平区护堤路206号陇头工业区

邮 编:

相关推荐

相关阅读

1、本信息由八方资源网用户发布,八方资源网不介入任何交易过程,请自行甄别其真实性及合法性;

2、跟进信息之前,请仔细核验对方资质,所有预付定金或付款至个人账户的行为,均存在诈骗风险,请提高警惕!

- 联系方式

公司名: 汕头经济特区震龙塑料机械有限公司

联系人: 黄馨锐

手 机: 13502966321

电 话: 075482125236

地 址: 广东汕头金平区汕头市金平区护堤路206号陇头工业区

邮 编:

- 相关企业

- 徐州恭乐橡塑机械有限公司

- 圣亨工业装备(江苏)有限公司

- 日水商贸(东莞)有限公司

- 广州速益自动化设备有限公司

- 青岛中邦凌电器有限公司

- 青岛中邦凌电器有限公司

- 广东科曼斯智能科技有限公司

- 上海盈固化工有限公司

- 阜新富澜德热能设备有限责任公司

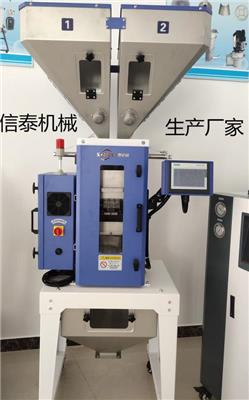

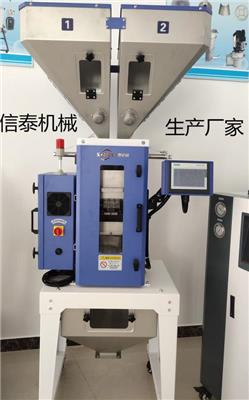

- 中山市信泰机械设备有限公司

- 商家产品系列

- 打包带

- 聚氨酯保温材料

- 蓝晶石

- 雷蒙磨

- 磷酸盐砖

- 铝矾土

- 捣打料

- 电子电器陶瓷

- 煤气发生炉

- 镁铬砖

- 镁砂

- 镁碳砖

- 莫来石

- 莫来石保温砖

- 耐材设备

- 耐火材料

- 耐火炉料

- 耐火泥

- 耐火水泥

- 耐火原料

- 耐碱砖

- 耐磨陶瓷件

- 泡沫石棉

- 包装机

- 保温材料

- 保温涂料

- 玻璃板

- 玻璃棉

- 玻璃面板

- 尖晶石砖

- 产品推荐

- 资讯推荐

¥8160.00

120度水式高温模温机 6 9 12KW 配水排带报警装置水温机

¥6200.00

¥7800.00

¥5000000.00

¥2100.00

¥21300.00