platinum curing silicone

- 时间:2019-08-07作者:深圳市红叶杰科技有限公司浏览:593

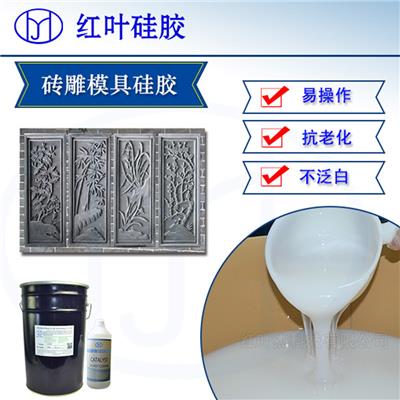

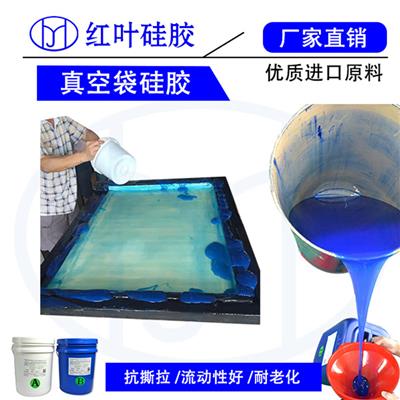

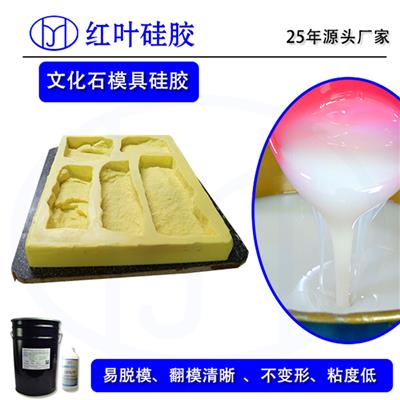

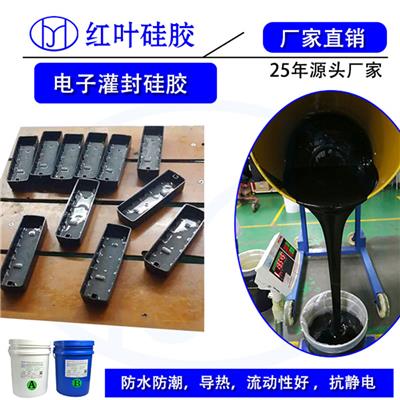

HY-E600 Addition Cure Mold Making Silicone Rubber

Description

HY-E600 is a kind of two part silicone rubber in addition cure or platinum cure type with mixing ratio of 1:1 or 10:1 . It can cure at room temperature as well as under heat . It’s a kind of food grade silicone and mainly used for mold making.

Application

HY-E600 silicone rubber is mainly used for making molds of concrete stone,GRC,polyurethane products ; wax, candle decoration ; rapid prototyping and tyre molds; chocolate,candy and similar products .

Technical Parameters

Model | Color | Mixing ratio (%) | Pot life (mins, under 25℃) | Curing time | Hardness ( Shore A ) | Tensile- strength (MPa) | Tear- strength (kN/m) | Viscosity (After A/B mixed ,mPa.s) | Shrinkage rate (%) | Elongation (%) |

HY-E600 | Translucent | 1:1 or 10:1 | 30-40 | 4-5(hrs under 25℃) 20-30 (mins under 60℃) | 0 | 3.5±0.5 | 5±0.5 | 3500±1000 | ≤0.1% | 300% |

Characteristics

*An exceptional fluidity and good operability, easy to demold

*Good tensile and tear strength

*Outstanding bubble releasing

*Non-deformation

*Low shrinkage

*Aging resistance ,high temperature resistance (200℃)

*Environmentally, food-grade

Operation instructions

Step 1: prepare the original molds

Prepare an perfect original mold and clean it totally before operation .

*Notes:Make sure your original molds and operation tool cleaned up totally to avoid uncure problem .

Step 2: Take 100 G part A and 100 G part B (Or 100 G part A and 10 G part B) and mix them evenly.

*Notes: Addition cure mold making silicon rubber is two part flowing liquid , Pls follow the step strictly:

1.Weigh the two part exactly by electronic weight..

If any part not in exactly weight , it may cause changing of hardness , or even cause uncure problem.

2.Mix part A and part B evenly.

Otherwise the silicon rubber will be partly solidified and this will give birth to difficulties in your final operation. What’s more, the finished molds will meet a short life. All of these will cause a waste of silicon rubber.

Step 3: Vacuum pumping

Without exception, this step takes less than 10 minutes. Otherwise, it will cause cross linking reaction, and no more further steps will be available.

Step 4: Pouring casting or Brush operation

*Notes:1. For simple pattern products we suggest use pouring operation way , which will be very easy to operate and demould. Pourable silicone require light viscosity which will be easy to flow smoothly and easy to de-air .

2.For delicate pattern products we suggest use brushing operation way , which can copy the pattern exactly . Brushable silicone require high viscosity which won’t be easy to flow away and easy to brush .

3. We suggest to set the silicone mold for another 12 hours after demould before put into large production .

Warm tips :

As addition cure silicone is a kind of platinum cure system ,which will be easy to cause uncure problem ,so

Kindly follow the tips below :

*Do not mix with liquid condensation silicone rubber or even the tool which used for condensation silicone

*Do not mix with organic matter which contains N, S, P organics and ionic compound like Sn, As,Hg, Ph,

*Do not add any pigment or powder into the addition cure silicone rubber without any testing to prevent uncure problem

Package

20KG/drum vacuum packing for part A 20KG/drum vacuum packing for part B

200KG/drum packing for part A 200KG/drum packing for part B

Shelf life

Twelve(12) months when stored under dry and cool place by original package under 25℃

深圳市红叶杰科技有限公司专注于固化剂不发泡型,高分子防潮封堵剂,BBS防凝露封堵组料,高分子防凝露封堵材料,人体硅胶价格,加成型硅胶,模具硅胶价格,胸垫发泡硅胶,自流平封堵材料等

词条

词条说明

模具硅胶不加固化剂能自然凝固吗?我的固化剂没有搅拌均匀,所以造成了模具部分已经固化,同时有些地方还很软,请问这些软的地方以后会逐渐固化吗?依据红叶模具硅胶厂的经验,模具硅胶加了硬化剂以后必须搅拌均匀,如果没有搅拌均匀,就会发生部分不固话现象。如果没有固话的地方48小时以后还不能固话的话,这块模具就宣告报废了,就不会固化了,只能把它清理干净后重新制作模具。我的固化剂没有搅拌均匀,所以造成了模具部分已

1、准备好容器及搅拌机或搅拌棒, 例:用两个相同容量的器具,将A组分和B组分两种组分分别用容器按等量的方式量好,然后将A/B两个胶倒到同一个大容器中搅拌均匀,模具硅胶外观是流动的液体,A组份是带固化成分的硅胶,B组份是硅胶。(注:A/B两组份一定要搅拌均匀,如果没有搅拌均匀,模具会出现一块已经固化,一块没有固化,甚至造成模具报废状况)。 2、较好能将搅拌好的硅胶用抽真空机进行抽真空,(如不抽真空

人体硅胶产品使用方法:将模具清洗干净,吹干,不能留有水迹,将A、B组份按重量比1:1混合均匀,经真空机脱泡后,灌在模具里面,操作时间视温度而定30分钟左右,固化时间(室温)2-3小时,加温80°C-100°C可在数十分钟内固化。比例误差控制在0.05之内。包装: A组份20kg,B组份20kg装。按非危险品运输,贮存期半年,密闭、防酸碱及杂质。

细节一:硅胶和固化剂要搅拌均匀否则会出现表干里不干,或者固化不均匀的情况,出现这种情况会造成模具的报废,要尽力避免。细节二:抽真空排气泡很多人认为常温固化的模具硅胶是不需要抽真空的,在不抽真空的情况下你做的模具里面可能会存在一定气泡,模具里面都有气泡这个模具抗撕裂还能好吗?细节三:根据产品选择操作工艺一般小产品选择倒模操作工艺偏多,但是如果这个产品尺寸很大,一定要用刷模,虽然灌模省工省时省力,但是

联系方式 联系我时,请告知来自八方资源网!

公司名: 深圳市红叶杰科技有限公司

联系人: 周先生

电 话:

手 机: 18938867521

微 信: 18938867521

地 址: 广东深圳龙岗区龙岗区坪地六联石碧工业区红岭一路3号A栋

邮 编:

相关推荐

相关阅读

1、本信息由八方资源网用户发布,八方资源网不介入任何交易过程,请自行甄别其真实性及合法性;

2、跟进信息之前,请仔细核验对方资质,所有预付定金或付款至个人账户的行为,均存在诈骗风险,请提高警惕!

- 联系方式

- 相关企业

- 湖南省港田新材料有限公司

- 东莞市美成橡塑科技有限公司

- 深圳市指南针硅胶科技有限公司

- 上海百纯贸易有限公司

- 襄阳科迅电子科技有限公司

- 惠州市富迩达科技有限公司

- 深圳市捌柒硅胶科技有限公司

- 苏州品一玻璃纤维科技有限公司

- 深圳市宏图硅胶科技有限公司

- 深圳市硅诚硅胶有限公司

- 商家产品系列

- 产品推荐

- 资讯推荐